Lightweight concrete can be specifically defined as super lightweight concrete or foam concrete. That means it is light and can easily be used for all sorts of applications. Foamed concrete is characterized by utilizing air that is enveloped in the cement paste, foam concrete are utilized as an example in maintaining buildings warm, as insulation, or in the generation of lightweight solids for floating processes. So if you want to experimented foam concrete on your own, onwards to the HOW TO series!

Sand it In: This is where you add the actual sand. Place the sand into the mixer, and mix well. Again: with the sand, you want to ensure that it is all mixed evenly in with the water and cement just like you did with the cement make sure not to forget this step!

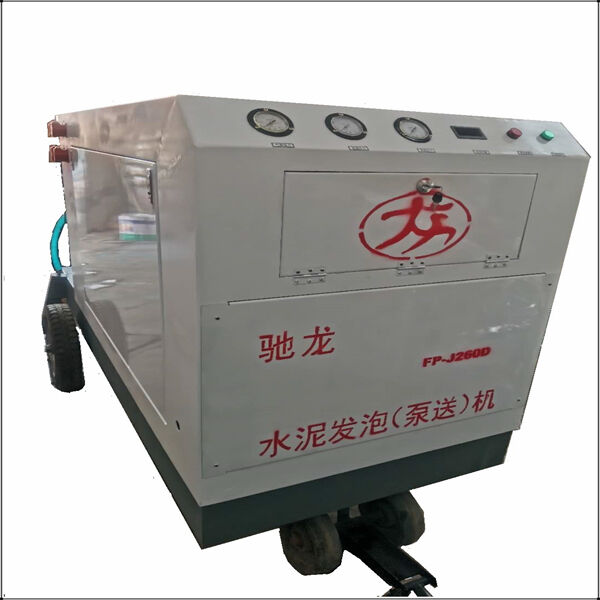

To Make Foam: After that, activate the foam-producing device. This is where the magic happens! Add the foam stabilizer to the generator unit. The foam generator will produce foam which is the magic part of your concrete that will make it float.

Combine it All: And last, put the foam into the mixer. Put everything into a bowl and mix well, but not too much. Make sure that you fold it in very well to ensure that the foam remains airy. It is the foam that gives the concrete its lightness and ease of use.

Select a Foam Stabilizer: The foam stabilizer is the most crucial component because it helps keep the foam formation intact. A good Foam concrete stabilizer will make a huge difference between the strength of your foam concrete.

Your foam concrete needs to be consistent. Which means how thick or thin it is. That will make your batter difficult if your mix is too thick. However, if it is overly thin, you will not be strong enough for use. These are some tips to achieve that right consistency:

Check: Test the foam concrete consistency aspects before using. That can be achieved by pouring a small amount into a mold and allowing it to dry. If it dries too thick or too thin then you can tune your mix somewhere in the neighbourhood.

Over the years have how to make lightweight foam concrete excellent working relationship with international logistics firms. Their top-quality service has helped the foam concrete equipment sell securely 60 countries across globe. We have capacity capability to send highly trained after-sales technicians to install, operate and market the equipment. few of customers can already offer local after-sales assistance. company offers spare part reserve for buyers who can benefit from it.

company's main business involves foam concrete equipment manufacturing as well as supporting technological innovation. company has the ability develop production and equipment will meet needs customers. can undertake how to make lightweight foam concrete research development projects. For example, in 2007 the company carried an initiative of national scale research construct a mobile roof insulation pump station. 2009, we undertook numerous projects with the People's Liberation Army, some which were incorporated military patents. In 2016, we completed a research project of Tsinghua University in China and in 2020, we began a non-ferrous metal mine safety mining project researched by China Gold Group.

company accredited by ISO9001, CE other certifications.In addition, holds more than 20 patents as well two invention patents such for our mine filling machine concrete that protected by independently intellectual how to make lightweight foam concrete rights. It designated an "National high-tech company".

Chilung its own R D department. Chilung developed six product lines, including 30 models, more 100 varieties of how to make lightweight foam concrete spare parts to satisfy requirements of every customer. Chilung been awarded more than 30 patents, participated developing various industry standards, and was close contact with design institutes universities.

Copyright © Yantai ChiLung Construction & Energy-saving Technology Co., Ltd. All Rights Reserved — Privacy Policy — Blog